- The purity of the hydrogen can be up to 99.999%, the dew point can reach -70°C

- The maximum pressure can reach 480psig (3.2bar)

- Flexible gas delivery: 30-100% adjustable.

- The operating pressure and the output are continuously adjustable below the rated value. The by-product is oxygen, and its purity is better than 98% before special treatment.

TECHNOLOGY

Hydrogen generation

Alcalyne Electrolyser

PEM Electrolyser

- The purity of hydrogen can be up to 99.999%, the dew point is ≤ -70℃, and the pressure is up to 3.2MPa.

- Product structure:

- Zero pole pitch, high activity SPE (PEM) catalytic electrode.

- Bipolar multi-element stack structure with excellent mass and heat transfer chemical process performance.

Wide Frequency Alkaline Water Electrolysis

- The new generation of wide frequency alkaline water electrolysis hydrogen production equipment can be directly applied to the equipment of wide frequency intermittent power supply, specially designed and developed for intermittent power supply of abandoned wind, abandoned light and abandoned water.

- It Reduces the intermediate power re-transmission to power grid under the P2G mode, reduce unit energy consumption, and greatly improve the project’s economic efficiency. The original “overload” electrolyser operation mode design makes the hydrogen production double in a short time.

Intelligent High Pressure Mobile Hydrogen Generation, Storage and Refueling System

- Small size and movable.

- High hydrogen purity (99.999%) and high pressure (35MPa).

- Applications:

- Hydrogen fuel cell UAV

- Off grid hydrogen power of communication base station

- Distributed renewable energy hydrogen power

- Small scale laboratory hydrogen

- Hydrogen fuel cell vehicle relay / emergency hydrogenation

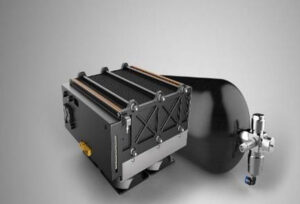

AEM Water Electrolysis Equipment

- Very low cost modular:

- High efficiency

- Simple and compact

- Available rain or tap wáter

- Powered by the grid or renewable energy

- Equipment characteristics:

- The capacity can be 0.5 to 10 Nm³/hr

- Each module produces 0.5 Nm³ or 500NL per hour

- Can be installed in a standard 19-inch cabinet

- Only 4.8 kWh per 1 Nm³ of hydrogen

- Can pre-compress hydrogen to 35bar

- Option to install a 99.999% purity dryer

Hydrogen compression and storage

Hydrogen auxiliary products involve compression and storage systems, among others. All integrated and adapted to different projects and industrial needs.